"Expanding Foam & Glued-on Mat" method of bathtub floor repair led to a costly bathroom remodeling

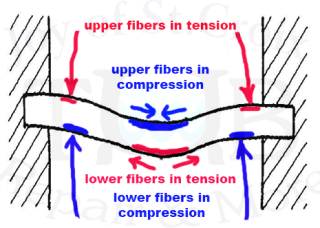

How does a bathtub floor break to begin with?

The customer was told that expanding foam would fix the problem

Instead of removing the damaged wood core and repairing the fiberglass, a ridiculous but very common method used by bathtub repair companies is to inject expanding foam and glue on a mat.

What is the

"expanding foam and

glued-on bathmat"

method of repairing a bathtub floor?

The expanding foam method involves using an expandable urethane foam originally used for flotation devices and taxidermy.

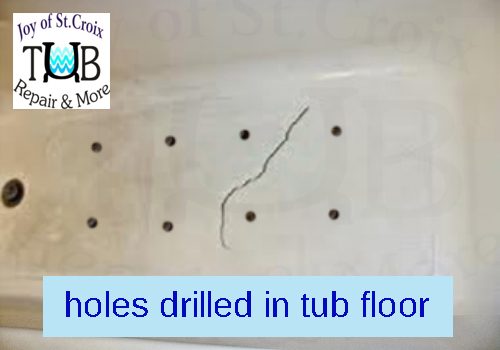

Holes are drilled in the broken floor and the foam is injected in the hope that it will magically expand only where it's supposed to be and provide a solid structural support to the bottom layer of non-repaired fiberglass and the non-repaired core. A two-part urethane adhesive is used to glue a mat onto the floor instead of reglassing the top layer and applying a new texture.

Let's examine a visual inspection of a failed "foam and mat" repair

We'll look at the video first and then take a closer look.

preliminary inspection

The purpose for placing the order was that the floor was weak and spongey where a person would stand to take a shower, and a crack was running from the drain to the front of the unit.

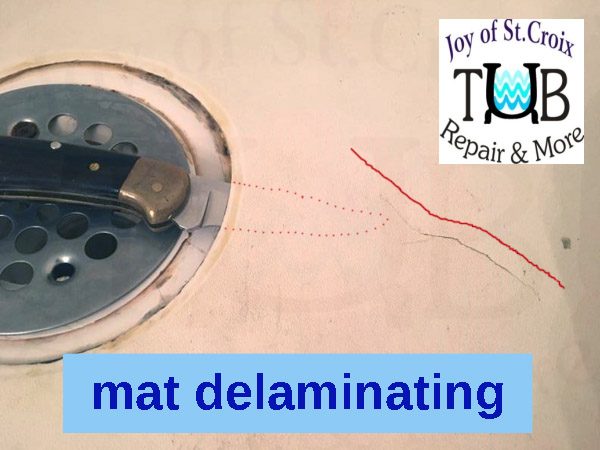

The first thing noticed was the presence of a glued-on mat - suggesting that the magic foam method was used, which unfortunately for the homeowner, turned out to be correct. A closer look at the glued-on mat revealed that it wasn't only cracked but delaminating. The reason for delamination is usually that the floor it's glued to has deteriorated and fallen away, and the crack rather confirms this. Water will have seeped into the delaminated area which will have extended to the original damage that was covered by the glue-on mat thus causing more damage.

exploratory inspection

The weak and spongey area had a slight but distinct pinkish discolouration on the glued-on mat. The four corners of the soft and sagging area wass marked out by drilling holes and then cutting out the the marked area. Two holes pulled up wood shavings from the core; one of which was water-logged and one showing dry-rot. Two holes pulled up no shavings at all indicating no core present in those locations.

invasive inspection

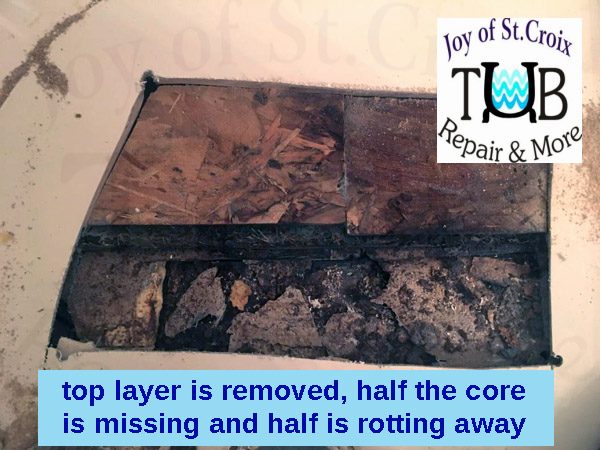

So far we know that the unit is broken and the damaged area needs to be removed in order to determine the extent and possibility of the repair. Holes were drilled at the four corners of the perimeter surrounding the floor's spongey area to remove a section of the floor and expose the subfloor. The top layer of fiberglass, with the mat glued to it, was completely delaminated from the core and lifted straight off. Many composite showers do not have a complete core but are constructed of various pieces of OSB (chipboard); a 12" x 30' area next to the drain running from the rear of the unit to the front was completely missing. The lower layer of fiberglass where the piece was missing was completely disintegrated.

condition of core

The remaining core in the inspection area was removed and examined. The core was completely rotted; dry rot in some areas and water logged in others. The lower layer of fiberglass was stained showing the path of water infiltration and pooling. The cause of the disintegration of the lower layer of fiberglass where the core was missing was the continual pooling of water that wicked in through the cracks in the upper layer of fiberglass that was never properly reglassed. Fiberglass is not water impermeable and will easily disintegrate under constant exposure. Without any support it readily collapsed under its oen weight.

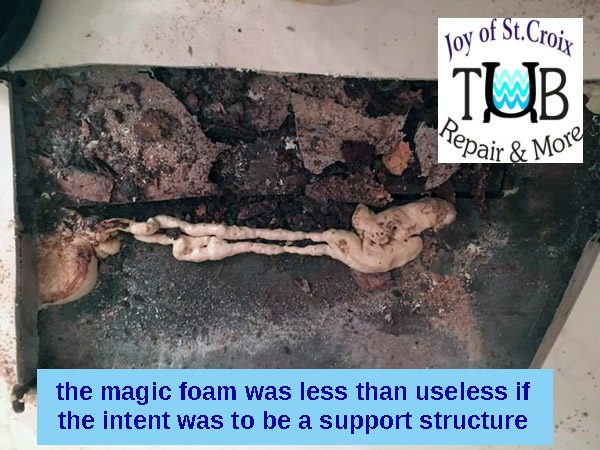

presence of expanding foam

The glued-on mat suggested that expanding foam was used, and unfortunately that was the case. One of the problems with expandable foam is that it's area of expansion is uncontrollable; it just doesn't go where you want it to or stay where it's supposed to. The mystery of why there was no foam around the drain area was solved when we looked under the house to examine the subfloor. They injected foam right out of the subfloor's access hole and into the basement. Another problem is that it acts as a sponge and holds water stagnant. The use of expanding foam in this instance was less than useless as open cell window insulation foam was employed instead of a closed cell flotation or taxidermy foam - it gave absolutely no structural support and was sparse and haphazard. In fact, it probably contributed to the need for replacement because it kept the subfloor wet rather than allowing the water to drain away, thus degrading the subfloor.

inspection's conclusion

The Inspection's conclusion was that the shower's floor had experienced catastrophic failure. While the shower's floor could be rebuilt the condition of the subfloor was too deteriorated to justify the expense. The final assessment of the Joy of St Croix field crew was that the shower unit be removed and the subfloor be replaced. This unit was deemed ineligible for repair by Joy of St Croix.

Joy of St Croix - Tub Repair and More

does not use expanding foam and a glued-on mat.

Joy of St Croix cuts out the damaged area and rebuilds the bathtub floor with support, fiberglass, and new core.